Account Manager

Applications Engineers

Logistics

Quality Control

Account Manager

A dedicated account manager provides support, including assistance with platform and file uploads.

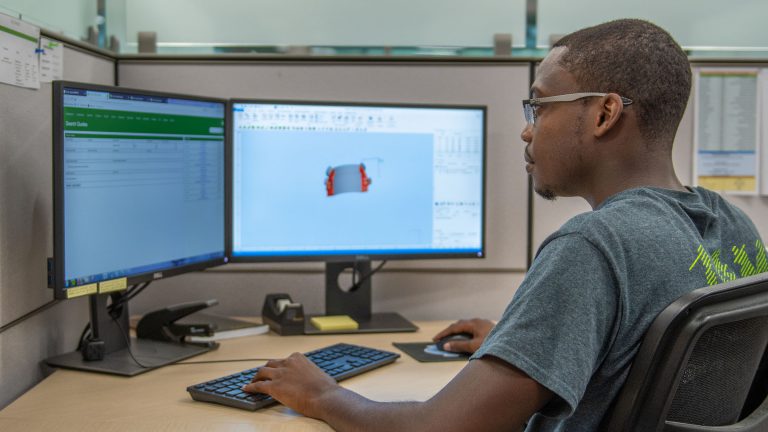

Applications Engineers

Expert CAD solutions and cost-reduction strategies tailored by in-house applications engineers to optimize your designs.

Logistics

Seamless logistics fulfillment and efficiency optimization from experienced operations specialists.

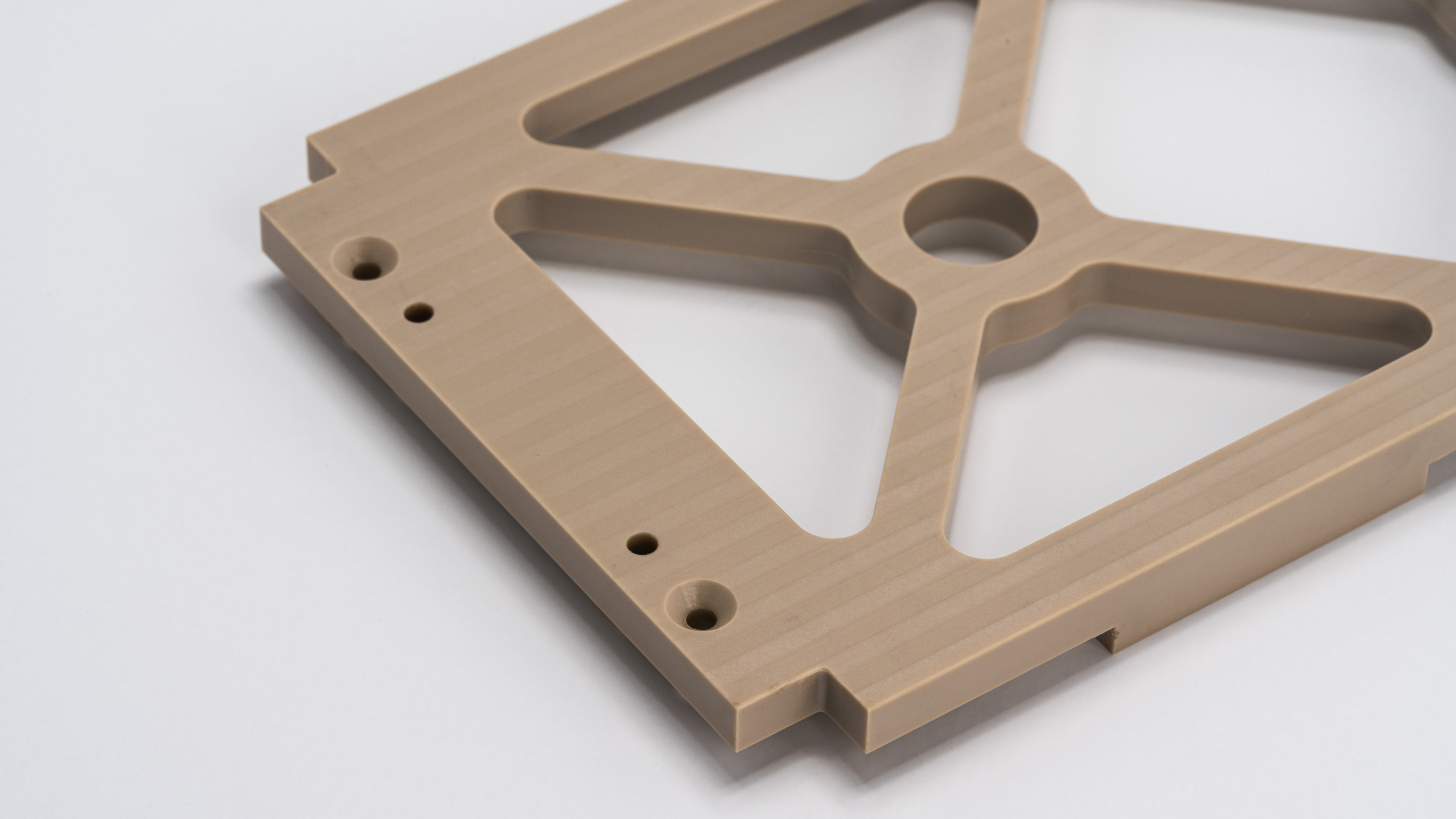

Quality Control

Our skilled expert on-site quality control teams ensure your parts meet your expectations and exact specifications.